Calcium carbonate

Calcium carbonate

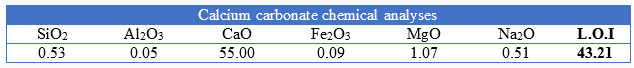

Calcium carbonate with the chemical formula CaCO3 is a white powder that has many uses as an additive in various industries. Calcium carbonate has a wide range of applications and today it is one of the consumables and required by industries such as paint, paper, rubber, cosmetics, paper, plastic, etc. Iran has large and high-quality calcium carbonate sources and mines, and it is also one of the exporters of the powder of this material to neighboring countries. According to the type of application, the calcium carbonate powder is crushed up to 2500 mesh. Some of the uses of calcium carbonate are mentioned below.

1- Dyeing:

One of the uses of calcium carbonate is in the dye industry. This material can replace a part of the TiO2 requirement as a colorant in emulsion paints (blue base).

Calcium carbonate is widely used in the paint industry due to its reasonable price, optical and mechanical properties. Excellent dispersibility in all colors, increase in brightness, increase in resistance to weather and wear factors, reduction in paint production costs, etc. are some of the advantages of using calcium carbonate in the paint industry.

2- Papermaking:

Calcium carbonate is used as a coating material in the paper industry and is considered a type of filler. Coating materials are used in papermaking to increase the quality of printing on paper. Among the advantages of using calcium carbonate in papermaking, we can mention things such as reducing

paper production costs, increasing the strength of produced paper, reducing damage to the environment due to less wood consumption, increasing paper resistance, better absorption of paint and ink, etc.

3- Plasticization:

The plastic industry is an important consumer of calcium carbonate, which is used to reduce the price of the final product of plastic production. Calcium carbonate is usually classified as a filler that improves physical properties such as heat resistance, dimensional stability, hardness and strength.

. Calcium carbonate is used in the production of various plastic products such as pipes, cables, disposable containers, etc.One of the important fields of calcium carbonate consumption is in rubber making. Today, rubber is an inseparable part of human life due to its wide use in the production of car tires, door and window seals, etc. In the rubber industry, calcium carbonate is used in order to create a better surface texture of produced rubber, to create a uniform and homogeneous composition of raw materials, etc. Also, the use of calcium carbonate in rubber production reduces the cost of production and increases the life of products.